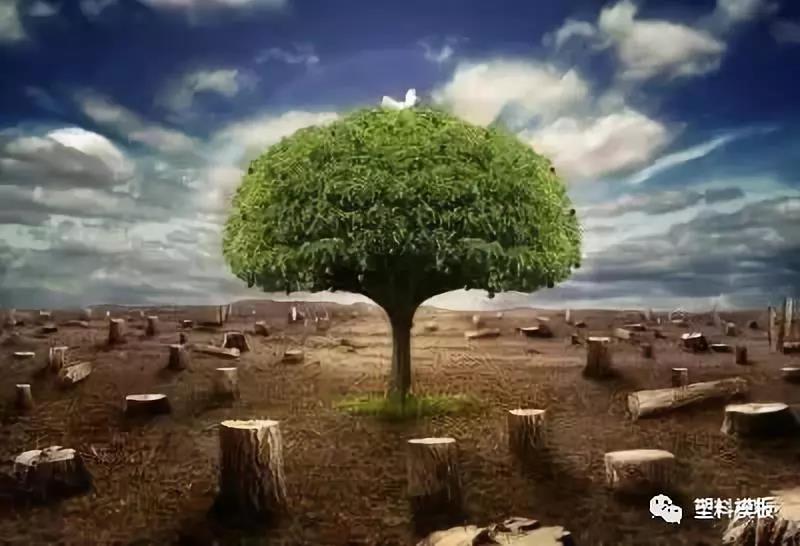

The report of the Nineteenth National Congress of the Communist Party of China pointed out that forest resources are the material basis for the construction of ecological civilization and the prerequisite and guarantee for sustainable economic and social development.

The truth is always there, don’t cover your eyes

my country is a big timber consumer country. In the construction industry, only the cost of building formwork is about 12 million cubic meters per year. For a long time in the past, wooden formwork accounted for most of the market share in the building formwork industry. my country's forest resources are scarce, and such a large demand for wood templates means that more tree resources need to be felled, which will destroy the forest vegetation and eventually lead to excessive logging of the forest, which will lead to the deterioration of the ecological environment. In addition, the production process of wooden formwork (plywood) includes the process of cutting logs—>gluing thin veneers—>hot-pressing and other processes. That’s right, the wooden formwork is made of many thin and thin boards that are hot-pressed together with glue. So it is also called plywood. The production process of this kind of board will bring serious problems such as water pollution, air pollution and solid waste.

In addition, my country's wood glued formwork materials mainly use plantation poplar and imported radiant pine wood, and the material is poor, resulting in low quality, low price and low turnover of wood formwork products. In addition, the disorderly competition and low-price competition in the domestic market are intensifying, and various costs are rising sharply. Therefore, many companies do not produce according to the standard in order to obtain profits. They are rough and rough, and the quality is uneven. On the other hand, how to deal with abandoned wooden formwork is also a rather difficult problem. If not dealt with in time, a large amount of wooden formwork piled up on the construction site will cause environmental pollution problems.

With the continuous development of society, wooden formwork has not been able to meet the development needs of the current building materials industry. In recent years, my country has introduced a series of major measures: In 2017, nationwide commercial forest harvesting was stopped across the country. In October 2018, the State Administration of Market Supervision and Administration issued a notice to cancel the management of production licenses for 14 types of industrial products such as "artificial board". In March 2019, seven ministries and commissions such as the National Development and Reform Commission jointly issued the "Green Industry Guidance Catalog (2019 Edition)", and "Green Building Material Manufacturing" was included in the "Green Industry Guidance Catalog".

According to current statistics, as of the end of 2018, nearly 50% of plywood companies in the country have been shut down.

Human beings are to save themselves, and it is themselves who do not pay attention to environmental protection and eventually perish

Why do you say that? Because many people think that the wooden formwork uses economic wood, which was originally planted for cutting, and has no effect on precious forest resources; the wooden formwork is relatively low in price, so the cost of input is less and it is more economical; in addition, Without production, there is no waste of resources and environmental pollution. Since someone produces it, someone must buy it. Therefore, environmental protection and environmental protection are entirely a matter of conscience. Such thoughts are terrifying.

Since there were living bodies on the earth, many catastrophes and catastrophes have been experienced, and many creatures have become extinct. The tremendous development of social productive forces has gradually made human beings separate from the fate of being dependent on nature and eating from the sky. Human beings are very powerful creatures. Human activities are based on consuming certain resources. They just think that when they achieve the same purpose, they should minimize the consumption of resources and minimize the pollution to the environment, so that this species of humans can last longer. Wouldn’t it be better to go down, not to extinction

From the construction industry, in fact, any part of it, such as the roof of the building, decorative panels, wall panels, and floors, can be replaced with plastic panels. Fujian Plastic Xinwang New Energy Co., Ltd. shoulders social responsibilities. In the field of replacing wood with plastic products, it has implemented the concept of green environmental protection, increased R&D investment, introduced new products in product research and development, and launched a new generation of building template system-Hollow Plastic construction template. Fujian Suxinwang has adopted a fully automated production line, which has not produced any harmful substances in the production process, and has truly achieved "zero emissions" of harmful substances. Plastic Xinwang hollow plastic construction formwork uses brand new raw materials, which has more superior performance and durable performance. It is far ahead of domestic similar plastic formwork. At the same time, it has many advantages such as high impact strength, environmental protection material, no pollution, self-moulding, and low price sharing. In the market, plastic formwork products "stand out" and are favored and recognized by the construction unit, which brings a good news for the development of construction materials and other industries.

In addition, Fujian Plastic Xinwang has also established a recycling mechanism for used and broken plastic templates to improve the comprehensive utilization rate and recycling rate of plastics and promote the recycling of resources. Obviously, this small step of Fujian Plastic Xinwang has become a big step in the building materials industry.

Farewell to the wooden formwork, we need to work together.